The History and Evolution of Envelope Overprinting Techniques

The History and Evolution of Envelope Overprinting Techniques Did you know that the art of envelope overprinting, once a laborious manual process,

This transformation has revolutionised how businesses communicate, blending creativity with efficiency. From humble beginnings to modern marvels, the journey of envelope overprinting is a fascinating tale of innovation and precision.

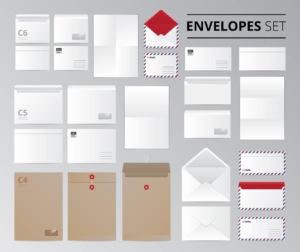

Envelope overprinting, the process of adding custom designs, logos, or text to pre-manufactured envelopes, has a rich history rooted in the need for personalised communication. As businesses sought to stand out in crowded mailboxes, overprinting evolved from simple hand-stamping to sophisticated digital techniques. This article explores the history and evolution of envelope overprinting, highlighting how technological advancements have transformed this essential aspect of business communication and what lies ahead for this dynamic industry.

In the early days of postal communication, personalisation was limited. Businesses relied on hand-stamping or manually inking envelopes with basic designs or addresses. This labour-intensive process was time-consuming and prone to errors, restricting its use to small-scale operations.

The introduction of lithography in the 1800s marked a significant leap. This printing method allowed for more intricate designs and consistent results, making it possible to overprint envelopes with logos and decorative elements.

By the early 20th century, offset printing emerged as a game-changer. This technique used plates to transfer ink onto envelopes, offering higher quality and faster production than lithography.

In the mid-20th century, flexography gained popularity for envelope overprinting. Using flexible rubber plates, it allowed for printing on various surfaces, including textured envelopes.

The late 20th and early 21st centuries saw digital printing transform envelope overprinting. Unlike traditional methods, digital printing requires no plates, enabling rapid setup and customisation.

Modern inkjet and laser printers have further refined overprinting. These technologies offer unparalleled precision and speed, making them the backbone of today’s envelope production.

Today’s overprinting methods offer numerous advantages for businesses:

These benefits enable businesses to enhance brand visibility while maintaining operational efficiency.

The future of envelope overprinting is poised for further innovation:

The evolution of envelope overprinting reflects the broader trajectory of printing technology, from manual labour to AI-driven precision. Each advancement, from lithography to digital printing, has made overprinting more accessible, efficient, and impactful. As businesses continue to prioritise personalised communication, envelope overprinting remains a vital tool for standing out in a competitive market.

Contact SAS Manufacturing for your overprinting needs and elevate your brand with bespoke envelopes tailored to your business goals.

The History and Evolution of Envelope Overprinting Techniques Did you know that the art of envelope overprinting, once a laborious manual process,

The ROI of Overprinting: Why Bespoke Envelopes Are a Smart Marketing Investment Introduction: The Unseen Power of First Impressions In today’s competitive

Quality Printed Envelopes: Elevate Your Direct Mail & Marketing Envelopes are more than just carriers—they’re powerful branding tools that ensure professionalism, security,

SAS Manufacturing’s Guide to Understanding UK Envelope Sizes Choosing the correct envelope size can be a challenge, especially when professional presentation and

Introduction In today’s fast-paced business environment, effective communication and marketing are crucial for success. Envelopes play a vital role in this process,

The Importance of Envelopes in Business Communication In today’s competitive business landscape, the importance of effective communication cannot be overstated. Envelopes play